| So beat the drum slowly And play the pipe lowly Play the dead march As you carry me along Dying Cowboy |

I define hum as a 60 cycle (or 50 cycle) unwanted electronic wave that gets into the audio part of your system. Most often it comes from the TT motor but it can also come from any device that runs nearby and there can be lots of such devices. It can be picked up by any wire not properly shielded. It can be introduced by any component, cartridge, turntable, pre-amp, sound card, amplifier, or speaker. You need to find the source of the hum by isolating it.

I suggest that earphones are used for these tests.

Noise is anything that does not hum, like clicking, or groaning, or excessive white noise, or a vibration or rattle, or white noise.

So lets start looking at the easy stuff first.

I have actually had instances where my record was producing hum. Find a good proven record and see if the hum goes away. If it does, case closed.

This is by far the most likely and usual suspect. There are five wires to a tone-arm, two signal wires, two signal grounds and a chassis ground (pronounced chasy, it's french). The chassis ground extends all the way from the cartridge base and head-shell base through the arm and plinth extending beyond to the shielding on the other four wires going to the preamp. It is connected to the chassis of the preamp. The chassis ground is meant to protect against outside electrometric interference and motor noise. It is very much needed since cartridge signals are not very strong. These three grounds are all separate and should never contact each other. The two signal wires are also separate.

A volt meter is needed for the following tests and a basic understanding of continuity and isolation. Remove the headshell or use a spare headshell without cart for testing. If you do have a spare headshell you can test the wires easily. Continuity check all five wires. Make sure to especially test continuity for the chassis ground against all metal parts including the headshell itself when mounted, arm, plinth and TT base and anything that is metal on the unit as well as the wire that goes to the preamp (there is also a small ground wire connecting the tone-arm tube to the plinth because the pivot pins are not good enough). Next run an isolation test on all five wires. All should be isolated. If not, you will have a hum problem. I have some more information here on turntable wires.

Play a record and disconnect TT ground to preamp. Any change? If hum goes away you have a feedback loop. Hum should increase when you disconnect the wire to the preamp. If no change in hum then chassis shielding is not working.

Turn preamp to max and put tonearm in rest position. Turn TT motor on. Turn TT motor off. Does hum go away or change? If there is no difference it is not motor noise may be wire noise. If noise goes away or decreases when the motor is off you have hum from the motor. Shielding or isolation may be a solution but it needs further investigation.

Massive platters are really quiet. That's why they are massive. Smaller platters can be noisy and can transmit motor noise because they can vibrate. Find a record with a large deadwax and clean it well. Drop arm very close to the end of record and Turn preamp to max. Listen to runout. It should not be excessive or hum but will indicate some platter noise and could generate a low hiss from record surface noise. But if no hum is detected then your noise is not from the platter.

Disconnect TT wires to the preamp input side. Turn preamp full volume. Usually it is set to around 4 or so. If no hum, your pre-amp is good. Solid state preamps are really quiet, like an incredibly -60 db. Tube preamps can have noisy tubes which carry the characteristic 60 cps hum.

What is left is the amplifier or computer. With an amp you need to test other input to see if the hum is only on the aux input. If it is on other inputs you have a noisy tube or circuit in your amplifier.

They do get hummy. Check the polerity. That's usually it. Some speakers need to be grounded to the amp. Change speaker. If new one is quiet, problem found.

Below is my basic setup - real basic. It goes from cartridge to tone arm wires to RCA cable to preamp to sound card. My preamp cable was shortened to 2 feet and double shielded. My sound card cable was 5 feet long and also double shielded (This cable can be longer). Other configurations that go into an amplifier can instead be plugged into a laptop and the signal can be analyzed with software. However even a laptop can introduce noise depending on the quality of the onboard sound card. The best of all is a signal analyzer.

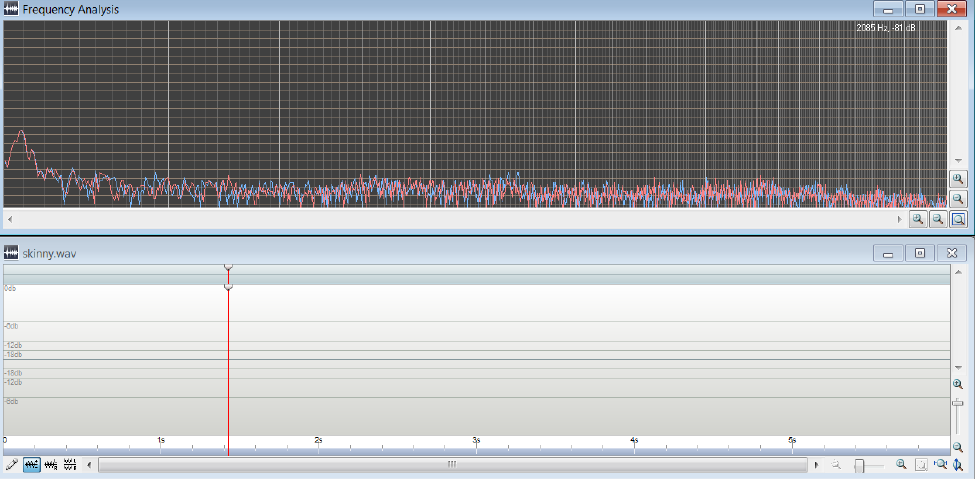

I struggled with a mysterious hum problem for some time. finally I looked at my sound card. As seen below after all the standard precautions were taken I was still getting a small 60 cycle hum way in the background. It was only slightly noticeable on soft passages and only between tracks. This test was on a Technics TT carrying an AT green cart using a recon SB sound card. Here is the signal in cartridge up position. All other obvious EMI was reduced as much as possible.

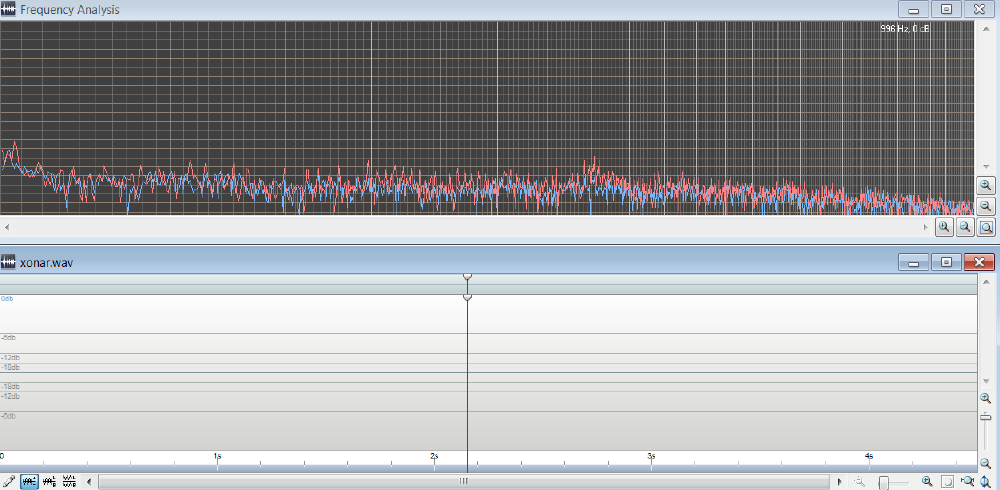

This 60 cycle spike pretty much pointed to the sound card as being the cause. I changed from a Recon SB to an ASUS Xonar DG and did a similar test, first with no cables then with cables and pre-amp volume full up. Here is the signal with cart up and it was noticeably better.

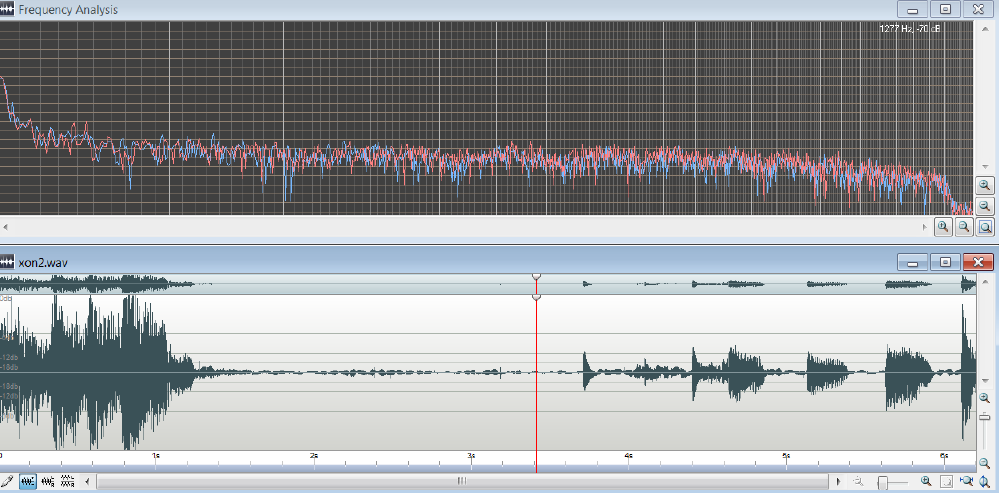

I also observed a much smaller 60 cycle spike but perhaps acceptable depending on what would happen in actual music recording. I recorded my usual selection taking a sample between tracks and was pleased with the results. This was on the same Techniques with an AT green. As expected the frequency drops off at 22k and the low end is more than good. There was no discernible 60 cycle spike. It does however show a very low frequency increase perhaps due to turntable rumble but it's well below 20 CPS. This passage was from Columbia BS2655, side two, between 1st and 2 song.

Pops are caused by imperfections or more often by minute dust particles that get trapped in record groves when handling or during play. Sometimes they can actually get there during manufacturing as suggested here. If a stylus wares to less than .6 or .7 mil at its rounded tip it then sweeps a larger area and starts to settle down to the bottom of the groove where more little imperfections lurk. The larger area a stylus sweeps the higher the chance of colliding with particles. Ideally the stylus should only touch the middle of the groove.