by

Dominic Vautier

1/2016

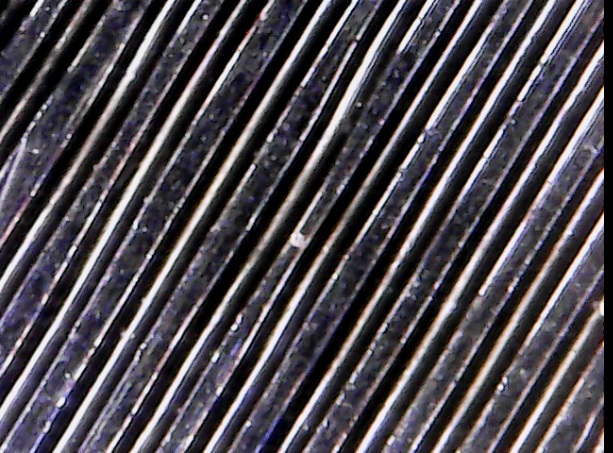

The standard microgroove record has around 250 grooves

per inch but this can very depending on content, cutter setting, cutter machine operator's preference,

desired quality or recording standards

of the

producer. It's probably hard to physically get much more than 300 grooves per inch without

reducing wall space between grooves too much. The

groove

itself at the top should average 1 mil wide set at 45 degrees but can be as large as 1.25 mils

or maybe as small as .8 mils. Good record companies try to keep the

average size

at one mil wide but the groove size is always changing depending on the kind

and volume of

the signal. The space between grooves still remains quite large, maybe 2 mils thanks to RIAA equalization which

reduces low frequency swings.

The standard microgroove record has around 250 grooves

per inch but this can very depending on content, cutter setting, cutter machine operator's preference,

desired quality or recording standards

of the

producer. It's probably hard to physically get much more than 300 grooves per inch without

reducing wall space between grooves too much. The

groove

itself at the top should average 1 mil wide set at 45 degrees but can be as large as 1.25 mils

or maybe as small as .8 mils. Good record companies try to keep the

average size

at one mil wide but the groove size is always changing depending on the kind

and volume of

the signal. The space between grooves still remains quite large, maybe 2 mils thanks to RIAA equalization which

reduces low frequency swings.

The two sides of a record groove are at 45 degrees to each other and carry different wave patterns for stereo but the same pattern for mono. Curiously then mono results in a hill-and-dale effect that Edison pushed so hard in his patents since both sides go up and down together.

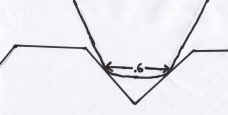

The stylus is

a diamond with a flat tip and rounded shoulders. To get around tight inside wiggles

the stylus

can have a flattened conical or elliptical shape but it's shape viewed straight on is

like what is in the picture.

The tip is wide enough so that

the two rounded sides of the stylus

come into contact with the groove optimally midway down the sloap. A stylus could measure .5, .6

or .7 mils from shoulder to shoulder, that is from the rounded edges (that's a little more than 1 two-thousand of an

inch, actually pretty small). A stylus

tip that

is too big will not follow the channel and could skip to the next groove

either before or after depending on anti-skating pressure. As

the sides of a diamond ware it begins to settle down into the groove and hit

more micro dust and manufacturing imperfections at the

bottom. The more it wares out the more likely it is to hit particles or

imperfections because the area the stylus shoulder sweeps becomes larger and

larger gaining no advantage in sound quality and picking up more noise. It's good to know that a stylus wares sharper, not duller and as it wares, begins to settle into the

groove and gets noisy hitting more and more unwanted debris at the bottom and top.

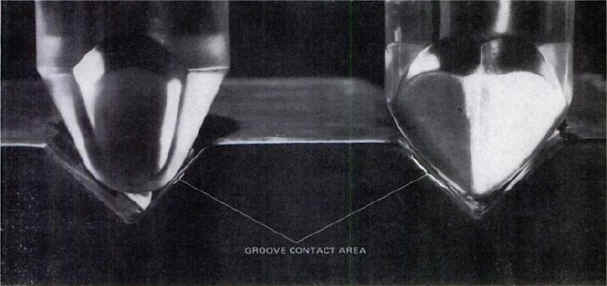

So a stylus never wares out as such. It only gets sharper. Below

is a picture of a good and a bad stylus. The good stylus touches only the

middle of the walls which should be the cleanest. The bad stylus

touches the whole wall.

The tip is wide enough so that

the two rounded sides of the stylus

come into contact with the groove optimally midway down the sloap. A stylus could measure .5, .6

or .7 mils from shoulder to shoulder, that is from the rounded edges (that's a little more than 1 two-thousand of an

inch, actually pretty small). A stylus

tip that

is too big will not follow the channel and could skip to the next groove

either before or after depending on anti-skating pressure. As

the sides of a diamond ware it begins to settle down into the groove and hit

more micro dust and manufacturing imperfections at the

bottom. The more it wares out the more likely it is to hit particles or

imperfections because the area the stylus shoulder sweeps becomes larger and

larger gaining no advantage in sound quality and picking up more noise. It's good to know that a stylus wares sharper, not duller and as it wares, begins to settle into the

groove and gets noisy hitting more and more unwanted debris at the bottom and top.

So a stylus never wares out as such. It only gets sharper. Below

is a picture of a good and a bad stylus. The good stylus touches only the

middle of the walls which should be the cleanest. The bad stylus

touches the whole wall.

Strangely enough, certain higher end turntables may not feature a limit stop and the cartridge gets to ride on dead wax for awhile which probably does it more good and prolongs life, since under normal play the stylus tip is never in contact. When it rides on the flat surface dead wax it gets a chance to "sharpen up" or rather "dullen up" a bit.

Older mono records had grooves cut that were slightly larger than one mill so a .7 mil stylus may sound quieter for monos.

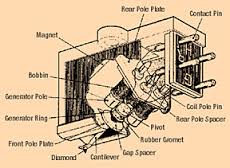

Almost all turntable cartridges work by magnetic

induction. A small v shaped diamond is fused to the end of a very

light tubular aluminum or carbon cantilever shaft. As the diamond wiggles over record

grooves a small electric

current is induced by a magnetic material on the other end of the shaft or

by other means which I will talk about below. The material is a secret

composite of epoxy, iron and maybe some cobalt or nickel. Only cobalt, iron and

nickel are

magnetic. Iron is the best but i suspect that secret compounds may be used.

Almost all turntable cartridges work by magnetic

induction. A small v shaped diamond is fused to the end of a very

light tubular aluminum or carbon cantilever shaft. As the diamond wiggles over record

grooves a small electric

current is induced by a magnetic material on the other end of the shaft or

by other means which I will talk about below. The material is a secret

composite of epoxy, iron and maybe some cobalt or nickel. Only cobalt, iron and

nickel are

magnetic. Iron is the best but i suspect that secret compounds may be used.

A typical mono setup with two magnetic coils.

Here is a picture of my Shure M55E which I got in 1965

and retired in 1985. It had many thousand hours of playing time and is

completely warn out. There is no shoulder. Notice how sharp it

is. It was warn to a point.

Here is a picture of my Shure M55E which I got in 1965

and retired in 1985. It had many thousand hours of playing time and is

completely warn out. There is no shoulder. Notice how sharp it

is. It was warn to a point.

My newer Shure M97XE is a few years old and the tip is still somewhat rounded as it should be. The pitch on this unit is 45 degrees. It still looks good but is a little noisy.

Each wall of a record carries a different set of

wiggles so the stylus shaft not only has to be able to vibrate very fast,

well up

to 20,000 times a second but

it has to generate two different vectors of signal to make stereo

sound. Each cartridge contains four magnetic cores wound with

many wrappings of fine wire, enough to generate a very feeble signal that

must be pre-amplified before being useful. There are two cores for each channel.

Each wall of a record carries a different set of

wiggles so the stylus shaft not only has to be able to vibrate very fast,

well up

to 20,000 times a second but

it has to generate two different vectors of signal to make stereo

sound. Each cartridge contains four magnetic cores wound with

many wrappings of fine wire, enough to generate a very feeble signal that

must be pre-amplified before being useful. There are two cores for each channel.

At the other end of the stylus shaft is just a dollop of magnetic material that is able to modify it's distance from one of the four metal cores. It can change its distance quickly or slowly and/or strongly or weekly, all depending on the record groove. That is basically how analog waveform is produced.

Grado is different. It has a needle arm rooted on a flexable base. In contact with it is an iron or cobalt like disk just above the root point of the shaft. Behind the disk are four small iron cores. When the stylus is mounted these cores change their distance from four larger wound cores in the cartridge body. This looks like a very cool design.

Back of stylus

The Grado resistance across the coils measure .771 ohm, a little higher then the others I looked at. A very cool design.

The stylus is in a shell and slides out. The needle shaft is anchored at the back but a small end sticks out and transmits the signal to four iron cores in the cartridge body.

The cartridge body has all four magnets close to the moving end of the shaft. coil resistance was .633 ohm.

The Shure stylus is the one I'm most familiar with. It is encased in a copper sleeve and then inserted into the cartridge body which contains the four wound iron cores. The stylus arm is anchored about two thirds of the way into the copper sleeve. At the other end of the shaft is magnetic material that interacts with the four coils on the body. This unit measured 1.231 ohm resistance on both sides.

I don't know why Shure decided to build their device like this.

Here is a typical sample of a stereo record groove. The passage is pretty quiet but there is a lot of room between grooves. You really have to compress them together to get any kind of groove hopping.

It is absolutely amazing how such a little bit of magnetic material at the end of a cantilever shaft moves to induce an electrical impulse as clearly demonstrated in the ADC above. The shaft acting like a lever is many times longer on the stylus side. The longer this shaft is the more sensitive the coils have to be since there is less movement of the magnetic material.

This raises the question of ambient electromagnetic fields or EMI (electromagnetic interference) which is all over the place and can generate cartridge noise even when a turntable is at rest or running in dead wax or on silent tracks.