Tonearm Hum Fixing

Some Ideas Anyway

| Aures habent et non audient.

Psalms 114

|

Grounding

A cartridge carries three different types of grounds. The

first two are the signal grounds, which are on the

negative end of the windings on the two magnetic

coils in the cartridge, the green and blue wires. These are unique connections that

need to remain isolated from the chassis ground, the black wire, until

these signals get safely into the pre-amp.

The chassis ground connects from the

shell of a cartridge (if it's metal) to the tone arm, plinth and metal body of the preamp.

If you have a plastic head shell there is no connection between the

cartridge ground and the tone arm. The chassis ground has one purpose, to shield everything from

motor noise and EMI (electrometric

interference). The chassis ground is not designed to play a part in

the signal, only to keep out

noise, and should not be connected to any part of the turntable

other than the tone arm. It only isolates the four signal and

ground wires

from cartridge to pre-amp.

The chassis ground connects from the

shell of a cartridge (if it's metal) to the tone arm, plinth and metal body of the preamp.

If you have a plastic head shell there is no connection between the

cartridge ground and the tone arm. The chassis ground has one purpose, to shield everything from

motor noise and EMI (electrometric

interference). The chassis ground is not designed to play a part in

the signal, only to keep out

noise, and should not be connected to any part of the turntable

other than the tone arm. It only isolates the four signal and

ground wires

from cartridge to pre-amp.

On my old Technics head shell I noticed that the green wire (right signal

ground) was soldered to the chassis ground. I removed this which

eliminated some of my low level hum.

I don't think that there should be any grounding done between the two

signal grounds and the chassis ground. This should be up to the

cartridge manufacturer but some of the earlier head shells did this.

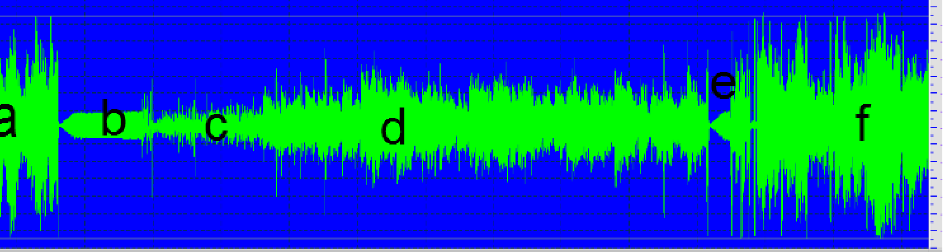

The signal produced was less hummy as shown below. It is probably

because I replaced the older head shell which was plastic. I like

metal headshels.

Rewiring Tone Arm

This is perhaps an extreme move but it will reduce

noise. There are two major parts to a tone arm, the arm

itself that moves up and down and the plinth or base that moves

horizontally. The arm is held to the plinth by

two needle screws that are secured on each side with locking nuts or bushings.

To replace the wires you just about have to back

off the pin bearings and slide the tube out.

This is perhaps an extreme move but it will reduce

noise. There are two major parts to a tone arm, the arm

itself that moves up and down and the plinth or base that moves

horizontally. The arm is held to the plinth by

two needle screws that are secured on each side with locking nuts or bushings.

To replace the wires you just about have to back

off the pin bearings and slide the tube out.

Your basic material are a replacement set of wires, solder and gun,

a small screw driver and spanner wrench. Additional materials may be

tape and feeder wire. It is always good to braid or plat the wire into 5

strands if you are going to all this trouble.

The spanner wrench can be

built by using an old screw driver and a grinding blade to make a gap in the

center so it looks like a fork. The set screws come loose easily with

a spanning wrench and

do not need to be very tight. Take pictures

of the position of the set screws before disassembling the tone arm.

The plinth does not have to be removed, but the arm does because it has

locking bolts underneath that remove the little spring loaded contacts.

It's smart to de-solder the wires at the breakout board so you can just

braid the new wires and replace if you want to.

Braiding

I think it is always a good idea to braid tone arm

wires but not too tightly. There are five wires and the braiding process is pretty simple

for odd numbered strands. If the existing wires are OK just braid them

and replace. If they are old or defective, de-solder the wires at the

breakout and remove from the tone arm. Braid and reinstall. Leave lots of extra wire in front of

the breakout board.

Covering Head Shell

Sometimes I like to shield any exposed signal wires on

the headshell. That

goes for the cartridge head which can also pick up EMI. I

took some aluminum tape and wrapped the head. It increases the weight but

can result in noise reduction. Here I have an ADC

stylus in a standard head shell.

Fade

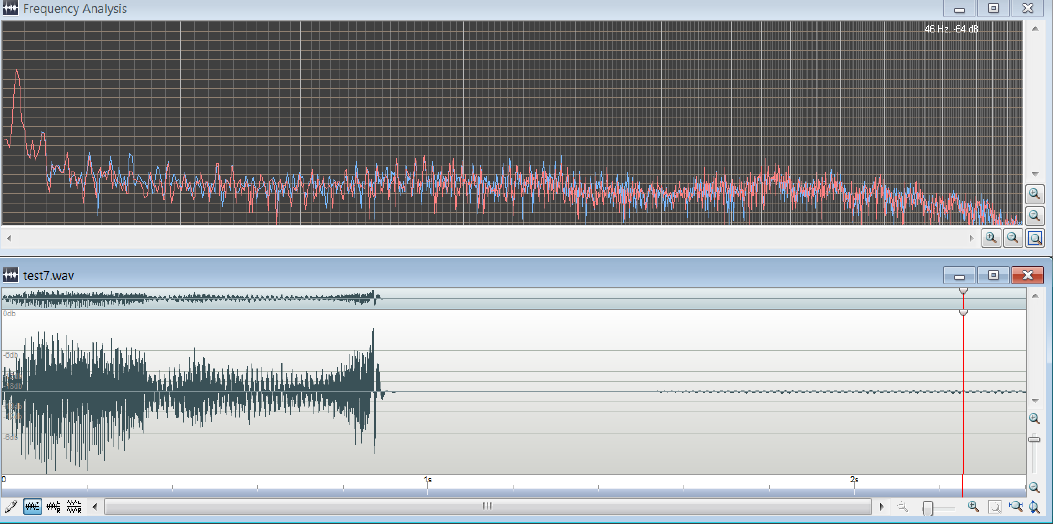

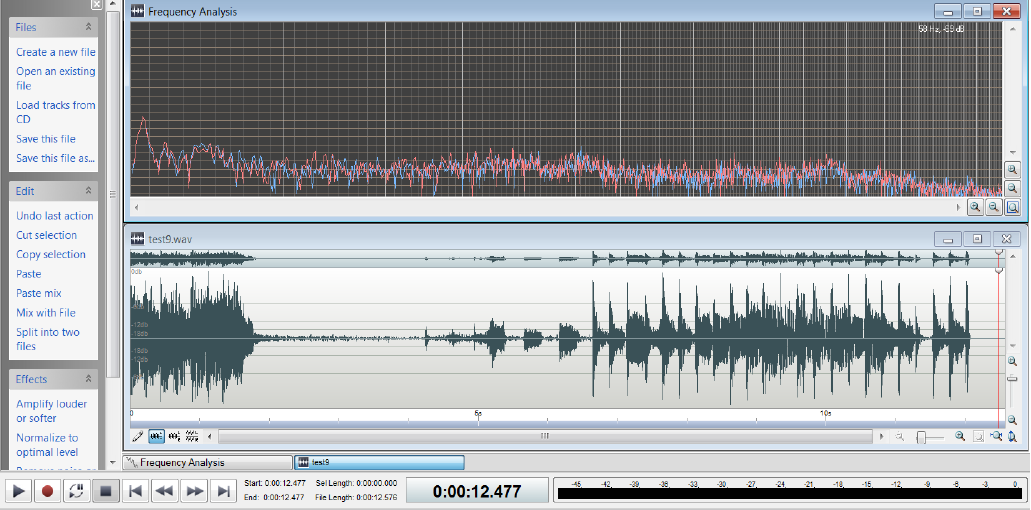

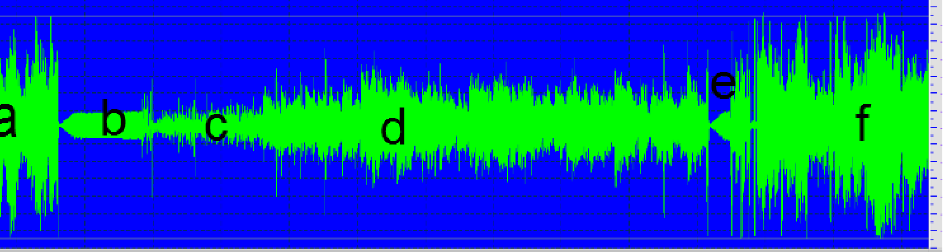

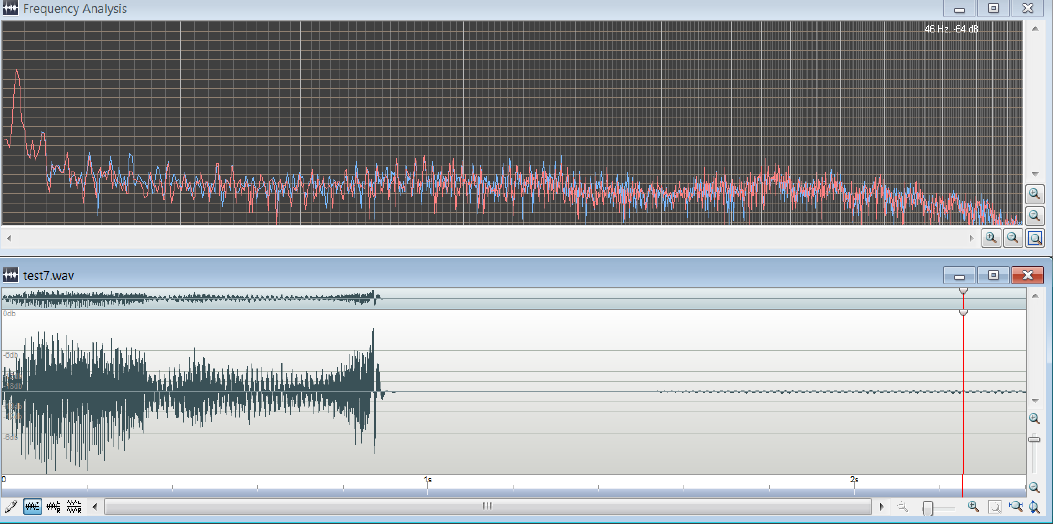

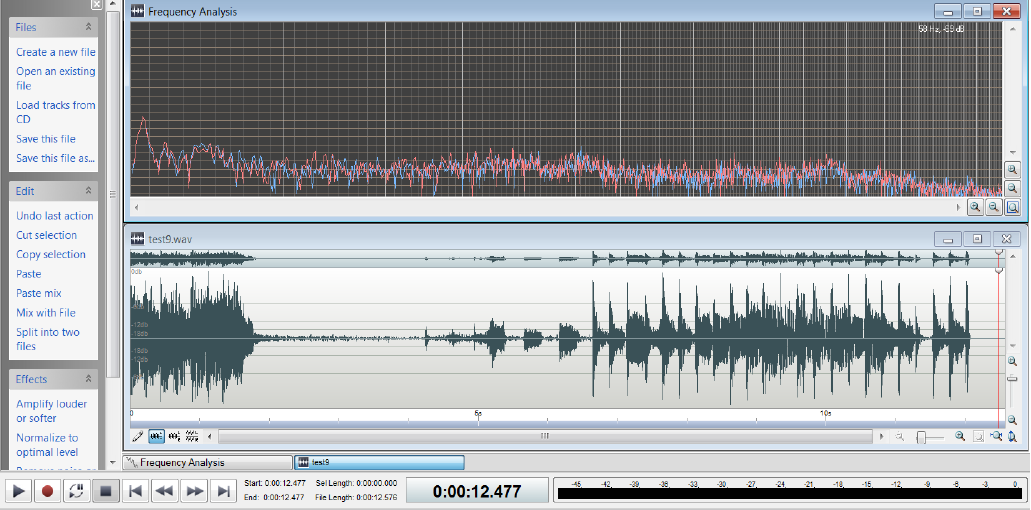

One thing I did notice was fading, that's what I call

it anyway. Notice below that a strong signal is recording and then the

stylus is lifted. The immediate result is good quiet but then a

gradual 60 cycle hum appears after one second.

This was my first indication I was getting feedback.

This had to lead me to suspect a noisy

sound card which was

introducing a slight 60 cycle spike after impedance dropped so I replaced

the sound card in my computer. The hum was reduced

noticeably.

The chassis ground connects from the

shell of a cartridge (if it's metal) to the tone arm, plinth and metal body of the preamp.

If you have a plastic head shell there is no connection between the

cartridge ground and the tone arm. The chassis ground has one purpose, to shield everything from

motor noise and EMI (electrometric

interference). The chassis ground is not designed to play a part in

the signal, only to keep out

noise, and should not be connected to any part of the turntable

other than the tone arm. It only isolates the four signal and

ground wires

from cartridge to pre-amp.

The chassis ground connects from the

shell of a cartridge (if it's metal) to the tone arm, plinth and metal body of the preamp.

If you have a plastic head shell there is no connection between the

cartridge ground and the tone arm. The chassis ground has one purpose, to shield everything from

motor noise and EMI (electrometric

interference). The chassis ground is not designed to play a part in

the signal, only to keep out

noise, and should not be connected to any part of the turntable

other than the tone arm. It only isolates the four signal and

ground wires

from cartridge to pre-amp.

This is perhaps an extreme move but it will reduce

noise. There are two major parts to a tone arm, the arm

itself that moves up and down and the plinth or base that moves

horizontally. The arm is held to the plinth by

two needle screws that are secured on each side with locking nuts or bushings.

To replace the wires you just about have to back

off the pin bearings and slide the tube out.

This is perhaps an extreme move but it will reduce

noise. There are two major parts to a tone arm, the arm

itself that moves up and down and the plinth or base that moves

horizontally. The arm is held to the plinth by

two needle screws that are secured on each side with locking nuts or bushings.

To replace the wires you just about have to back

off the pin bearings and slide the tube out.