| Reporter: General, do you read

the bible? George S. Patton: Every God damn day. |

D Vautier

6/2019

Devices that keep time have been around for many thousands of years; water clocks, sundials, and sand clocks to name a few. But the first true mechanical clock was invented way back in 1360 by Henry de Vick for Charles V of France (Milham, 81). No-one really knows how well it ran or even how it ran at all because it was upgraded so many times and no records were kept. This clock, or rather its decedents and upgrades are still in the Palais de Justice in Paris.

A good clock in

those days was lucky to keep time to an hour per day, but none of these

clocks were movable and nobody knows how they were built or how well

they ran. Most of the clocks

in later centuries were constructed in churches and bell towers and did

not move anywhere. The amazing thing is that it took a good 400

years from de Vick’s first feeble efforts at clock making to have it evolve enough precision

to be useful, and it took a good deal longer to make a portable clock.

A good clock in

those days was lucky to keep time to an hour per day, but none of these

clocks were movable and nobody knows how they were built or how well

they ran. Most of the clocks

in later centuries were constructed in churches and bell towers and did

not move anywhere. The amazing thing is that it took a good 400

years from de Vick’s first feeble efforts at clock making to have it evolve enough precision

to be useful, and it took a good deal longer to make a portable clock.

Clocks were not movable for a number of reasons. Their power supplies were weight driven because it was the only way to achieve even tension and any kind of motion would disturb that tension and make the clock run fast or slow. Clocks with verge escapement were particularly sensitive to changes in source power. And they were big, really big usually bigger than a refrigerator, and not so easy to carry around in a pocket.

About 1500 (150 years or so after de Vick) some cleaver clockmakers in Nuremburg Germany came up with a type of coiled spring as a power source but it suffered from uneven power output which made clocks run fast at first then slower later. But in 1525 Jacob Zech ingeniously invented the fusee, a stepped reel that equalized the power output of a coiled spring. This solved only part of the portability problem and some of the accuracy problem.

Around 125 years later in 1656 Christiaan Huygens invented the pendulum clock which was immensely more accurate and apparently could keep time within a whole 5 minutes per day. It was still not portable. Huygens lost interest in clocks and went on to do other great things. It was amazing that now 300 years had passed since the time of de Vick and still very little in the development of clock-making had occurred.

The 1700s changed all that. It was an extremely accelerated period of development because a collection of great clockmakers appeared; John Harrison (foremost), John Arnold, Pierre le Roy, Thomas Earnshaw, Larcum Kendall, Thomas Mudge and so many others came on the scene. So much was developed in so short a time! By the end of that century accurate and reliable portable sea clocks could be carried in the palm of the hand. These inventers had overcome the apparently insurmountable portable clock problems described by Newton in detail, such as dampness, temperature change, humidity, and the extreme turbulence experienced at sea. I stress sea clocks because so much importance was placed on ships being able to determine their position.

The inspiration for all this burgeoning scientific achievement was money, support, fame and opportunity offered by various governments, especially England which was the largest sea power during that century (1700s) and had the most to gain by solving the location problem with the use of very accurate portable clocks.

There was a rough idea that a day should probably be 24 hours and a day should start at midnight based on Roman tradition, but most people considered sunrise as the start of a day and sunset end the day and didn't care too much about it. How an hour was divided was questionable at first; quarters, halfs, tenths, but it seemed that sixty was a good number based on Babylonian tradition which the Romans wisely used.

Mechanical clocks have evolved into four more or less distinct functioning parts, the power supply, the gear works, the hands or hour-minute-second indicator and the escapement. By far the escapement was the most critical. The gear works transmit power at a measured rate to the hands which tell time or ring a bell or do something.

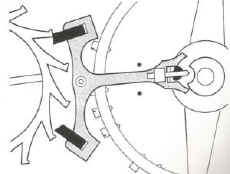

The power source can be a weight but it renders the clock non portable. A coiled spring is portable but needs to offer a consistent force as it unwinds. This was done by placing the spring in a barrel mounted on a pinion. The barrel uncoils a small chain which pulls on a fusee device equalizing the tension as shown above. The fusee is attached to a gear train.

After many years of design a more or less optimal gear train was developed and is shown here. The fusee, a stepped device to equalize tension, is commonly designed into the great wheel or main wheel. The main wheel drives a “second” wheel or hour wheel. The hour wheel then drives the third wheel or minute wheel. The third wheel drives the forth wheel or second-hand wheel. The forth wheel is retarded by the escape wheel which is connected to the escapement.

Hands are connected to the main, third, and forth wheel as indicators of hours, minutes and seconds.

There were all kinds of escapements invented during the 1700s. Pendulum clocks used dead-beat, anchor and grasshopper escapements, very simple stuff tied to and driven by the escape wheel connected to the pendulum. Harrison invented the grasshopper during his early period working with stationary pendulum clocks. He then invented the gridiron pendulum which did not change length with changes in temperature. his greatest contribution was the verge escapement for his famous H4 watch which won him the Board of Longitude prize. Thomas Mudge soon refined the detent escapement, inventing it in 1755. This is pretty much used today, but has been improved upon by later inventors.

The detent

escapement consists of four main components; the balance wheel,

the spring, the pallets & fork, and the escape wheel. The escape wheel is loaded (it gats power from the gear train),

and it applies pressure through each of the pallets to the fork. The fork is released by a moving balance wheel.

As the balance wheel releases the fork

it gets a little kick by the

fork along the way as it goes by giving the balance wheel enough spin

for the next cycle.

The detent

escapement consists of four main components; the balance wheel,

the spring, the pallets & fork, and the escape wheel. The escape wheel is loaded (it gats power from the gear train),

and it applies pressure through each of the pallets to the fork. The fork is released by a moving balance wheel.

As the balance wheel releases the fork

it gets a little kick by the

fork along the way as it goes by giving the balance wheel enough spin

for the next cycle.

The

balance wheel is extremely sensitive to temperature which can make the

clock run fast of slow if it expands or contracts. The wheel consists of two strips of metal, one

of brass on the outside, one of steel on the inside. Temperature change forces the wheel gaps to close but the wheel does not

change in size. In this way it retains it’s width since

the steel expands slower than the brass and that has a lot to do with

the clock running at a constant rate. That's

the reason for two gaps in the wheel. Much of this technology was developed by Harrison and his

contemporaries.

The

balance wheel is extremely sensitive to temperature which can make the

clock run fast of slow if it expands or contracts. The wheel consists of two strips of metal, one

of brass on the outside, one of steel on the inside. Temperature change forces the wheel gaps to close but the wheel does not

change in size. In this way it retains it’s width since

the steel expands slower than the brass and that has a lot to do with

the clock running at a constant rate. That's

the reason for two gaps in the wheel. Much of this technology was developed by Harrison and his

contemporaries.

Sea clocks were known as regulators or marine chronometers because of their high quality and accuracy.