Aures habent et non audient

D. Vautier

built 1/15

There are a lot of things that can generate unwanted noise as you copy music from an LP to your PC. Four principal items are needed and can be responsible for noise; the cartridge, turntable, preamp and sound card. From these four items you can usually eliminate preamps and sound cards because they produce noise far below audible levels, like -110 db or so below signal. But there are other things to consider.

This noise is practically imperceptible on any half decent turntable manufactured in the golden years of the 1980s and 1990s. Iím talking about .03 % or lower which is really negligible. Any platter with enough mass can turn steadily and easily exceed all human perception. I have even cheep turntable tin platters that spin so well that it is hard to detect wow or flutter.

Some cartridges are noisier then others. But you can do things to improve. If you keep the wires as short as possible from the head unit to preamp you will probably get below -90 db s/n and keep the preamp power supply a safe distance away from the preamp itself. The wires from cartridge to preamp should be very fine and shielded, the smaller and shorter, the better. Cartridge magnets produce just so much energy and these signals can be weakened by larger or longer leads. Once it gets to the preamp you get a good strong signal.

I noticed that when some cartridges are at rest they do seem to generate noise in the 60 cycle range usually at about -100 db way below signal. Or it could be that since nothing else is going on with those magnetic coils other stuff gets inside. I notice that when my stylus hits the surface of a record the background humm disappears completely or is totally swallowed up by record surface noise. There should be a spec in the cartridge description called s/n when at rest but I only mention the cartridge noise at rest because nobody else does.

Rumble will not be a problem until you start digitizing at a higher sample rate and bit depth and actually start paying real close attention to music quality. I notice that the better TTs that advertise lower rumble are direct drive. Yet the really good ones like to use belts. Direct drive motors can't be separated from the platter so they have an inherent rumble problem that can only be eliminated be spending more money on motor design. Hysteresis synchronous motors do generate some rumble but it can be kept low. Good belt drive TTs can isolate the motor and platter but there can still be belt noise. My Technics SL-D212 advertises a -78 db rumble which is way acceptable for most humans, still it is quite detectable for me when I listen for it carefully. By detectable I mean listening to lead in areas and soft areas with studio earphones at high volume. This rumble would not be too detectable with speakers and can be filtered out. I hate filters.

Most of the Technics made about this time (late 1980s) tied the direct drive motor assembly and tone arm to the whole unit. I'm not so sure this is a good idea but they did get the rumble down to -78 db s/n so that's not bad.

So I began to study my Sony PS-454 which was made in the mid 1980s, a fairly decent unit. It consisted of a similar hysteresis synchronous direct drive set on an aluminum platform mounted to the Bakelite chassis. The motor was mounted mounted independently.

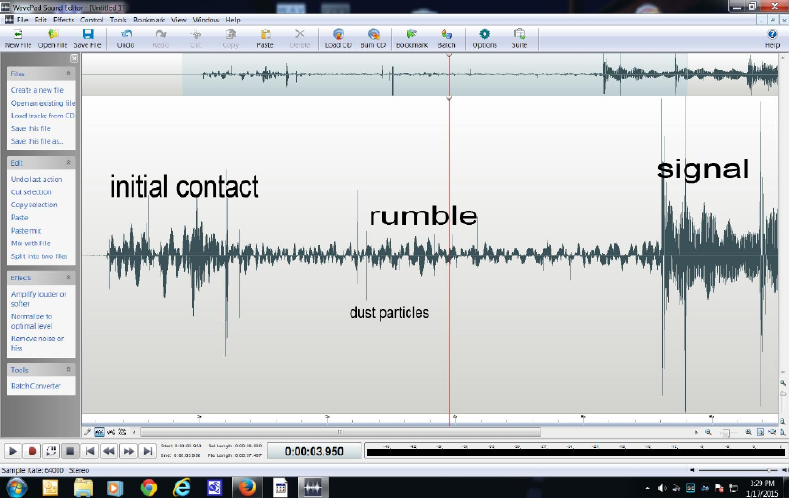

The above is an opening track on my SL-D212 which clearly shows the rumble just after initial stylus contact. Dust particles can be seen as small spikes in the waveform.

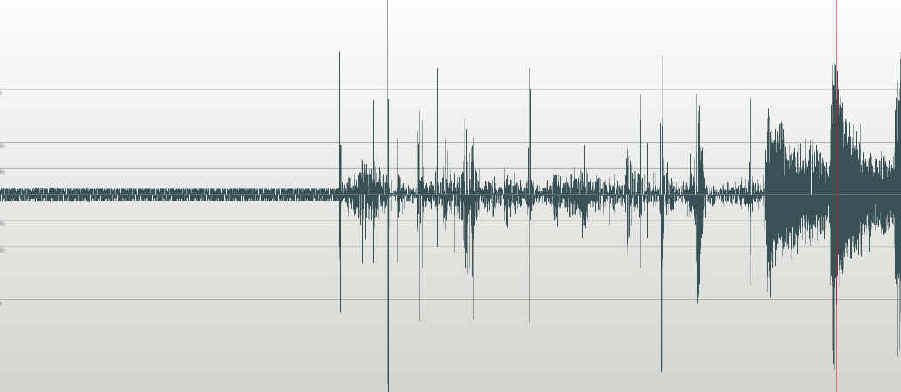

Above we see an example of greatly enlarged cartridge noise before it comes in contact with the record. the cartridge humm immediately goes away as the cartridge magnets start to work when they contact the record surface. Then the signal takes over after lead in.

I know my Sony has a higher rumble than the Technics but other than that it's a good TT and operates just as well in most aspects. It uses a straight arm as opposed to the wiggled arm but this does not seem to be a problem when using elliptical stili.

So I cut the mounts back enough to allow me to suspend the drive assembly on rubber bushings. This isolated the motor from the rest of the assembly. I did this to see if I could lower the rumble. I noticed that the rumble was somewhat lower but not quite as good as the Technics. The rumble was steady whereas the Technics SL-D212 rumble goes up and down as the platter turns, probably a design flaw. I suppose the lowest possible rumble occurs when there is a belt drive and the platter is supported independently by rubber mounts and you have a lot of money to spend.

The entire issue of rumble and other assorted undesirable noises depends much on record manufacturing quality. I have found some really good brand new records as well as some really bad brand new records. I have even found records that have their own rumble built in. It all has to do with how the record is made, the age of the stamper and how dust free the environment is. From the videos i have seen on vinyl record production it's a wonder we have any good quality records.